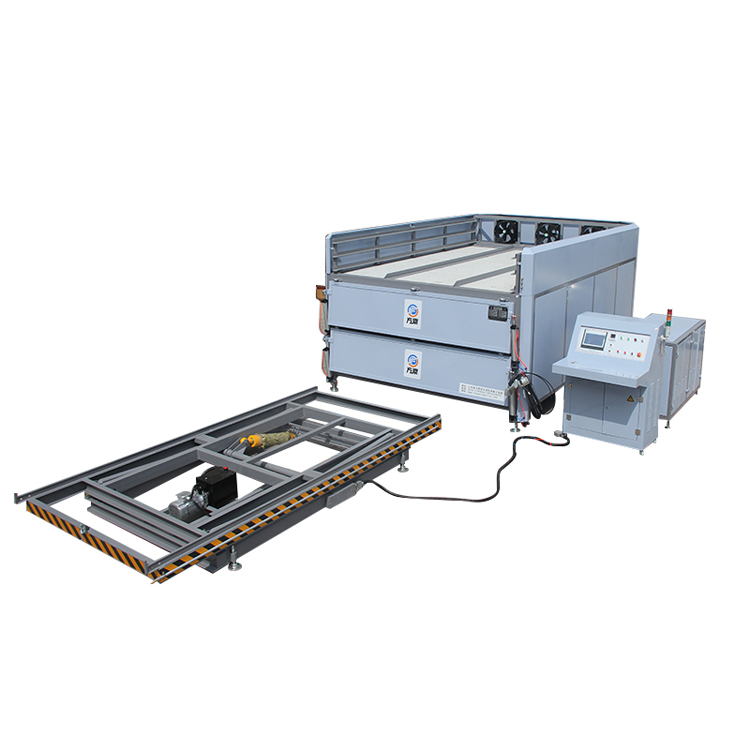

Izendlalelo ezine ingilazi lamination umshini nge ombaxambili ezimele uhlelo

IzakamuvaI-Fangding 4-ungqimba lwengilazi yomshini wengilazi isingeniso

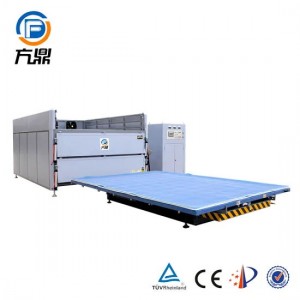

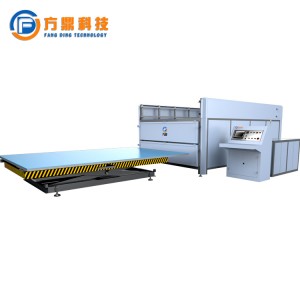

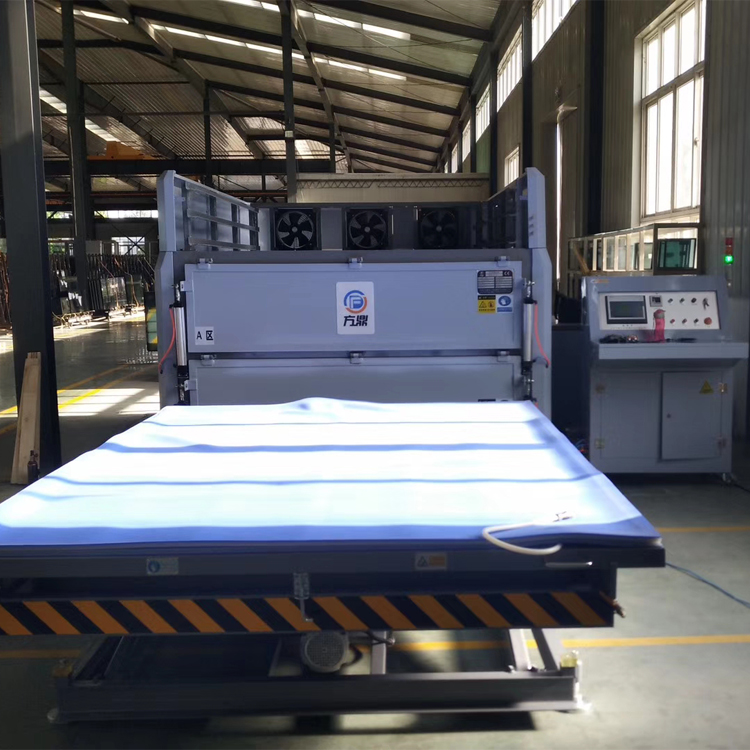

Umshini wezingqimba ezi-4 ofakwe uhlelo oluzimele oluphindwe kabili. Ikakhulukazi uhlelo lokusebenza luhlanganisa ukufudumeza, i-vacuum, isilawuli se-PLC, itafula lokuphakamisa ingilazi, ukupholisa.

Ikhabhinethi yokulawula ye-PLC yamukela ukwakheka kohlobo lwepiyano, kulula ukuyisebenzisa, ukubukeka okuhle futhi kuzoba lula kakhulu ukubhala phansi noma ukubeka okuthile.

Amaphampu we-vacuum kanye nezakhi zikagesi ziyahlukaniswa, ukuze kunganciphisa umonakalo ezintweni zikagesi ezibangelwa ukudlidliza kwepompo ye-vacuum; ngcono impilo yesevisi yalezo zingxenye eziyisipele.

Vacuum

Isistimu ezimele kabili:

Imishini esezingqimbeni ezine ifakwe uhlelo oluzimele olukabili, okusho ukuthi izingqimba ezimbili eziphezulu nezimbili ezingezansi zisetshenziswa njengamakamelo amabili ahlukene ngaphandle kokuthintana. Izinhlobo ezahlukene zengilazi elaminethiwe zingakhiqizwa kanyekanye.

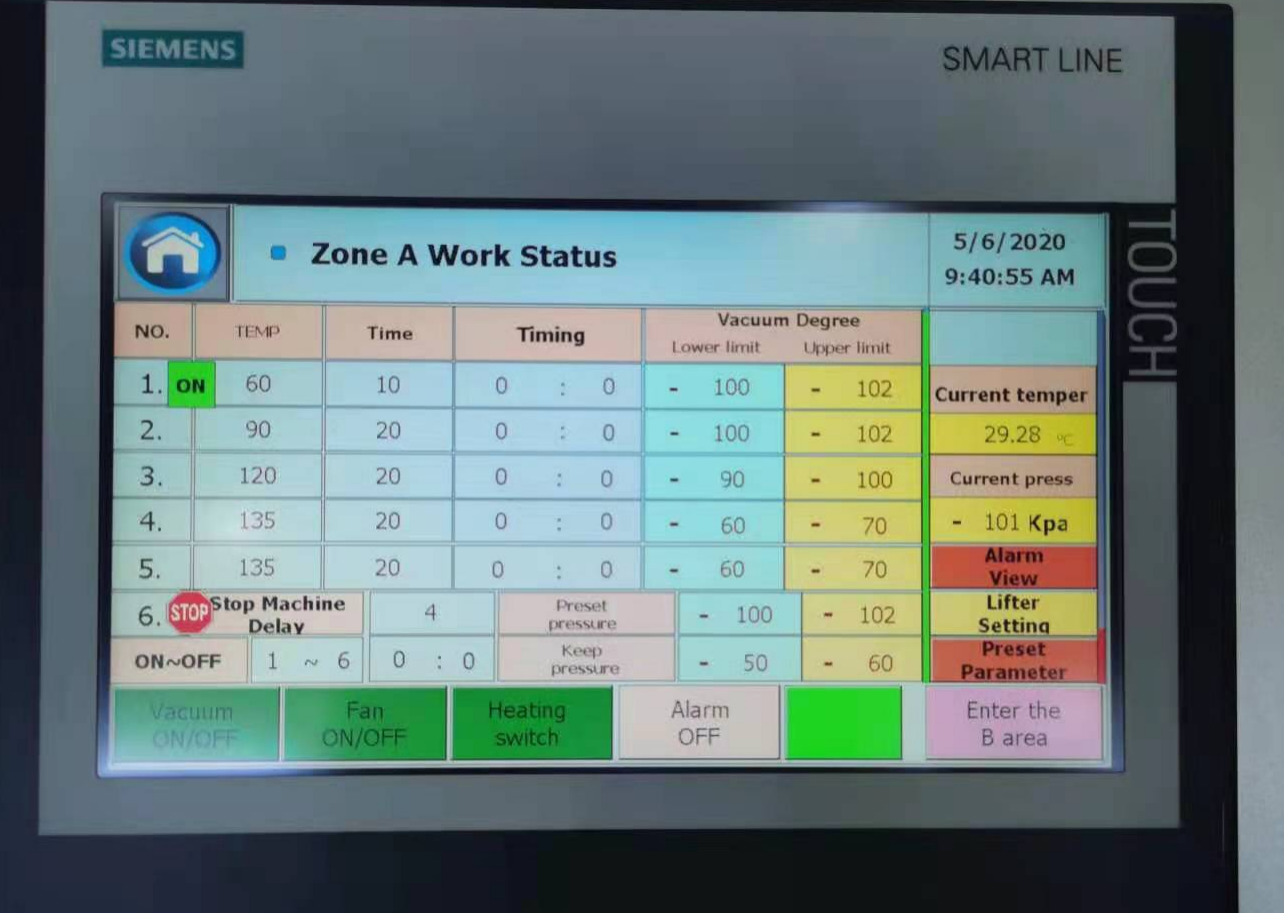

SiemensI-PLCLawulaSuhlelo

Kunamasethi ama-2 amaphampu evacuum apholile, angasebenza ngokuqhubekayo amahora angama-24. Futhi ithangi le-buffer liyengezwa ukuvimbela ukungena komoya esikhwameni se-silicone uma kucisha kungazelelwe. Futhi sihlomise idivayisi yokuhlukanisa umhwamuko wamanzi, ukuze ibe yinde impilo yesevisi yephampu. Zombili ziyilungelo lobunikazi lethu elikhethekile.

Ukushisisa

Samukela ishubhu yokushisisa okungenasici, ukushisisa ngokushesha nangempilo ende ewusizo. I-turbo fan yangemuva yenza ukujikeleza komoya oshisayo ku-convection esithandweni. Umphumela wokushisa ngemisebe ungcono kakhulu, ukusatshalaliswa kweshubhu lokushisa njengokhaphethi, zonke izikhundla zengilazi ziyashiswa, qinisekisa ukuthi ingilazi ithola ukushisa okufanayo futhi ithuthukise isivuno.

Idizayini yezinga lokushisa enezigaba ezinhlanu.

Ungasetha amapharamitha (izinga lokushisa, isikhathi, isikhathi, idigri ye-vacuum) abe yizigaba ezi-5. Imodi yokushisa ye-modular, ukulawula izinga lokushisa okunembe kakhudlwana.

Ikhabhinethi yokulawula

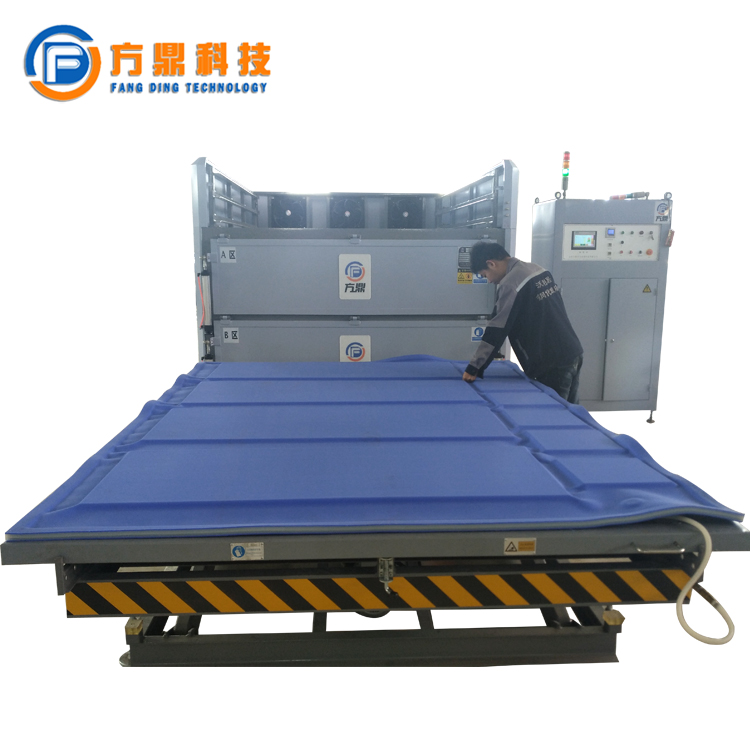

Itafula lokuphakamisa ingilazi

Isiteji esiphakamisayo sithatha imodi yokuphakamisa ikheshi, engafinyelela kunoma iyiphi indawo. Vele ukhethe inombolo ethile yongqimba yesikrini sokuthinta bese ucindezela inkinobho, ngale ndlela, sithuthukisa izinga lokusetshenziswa kwemishini. Ububanzi betafula buyi-1800mm esikhundleni se-1355mm, onokwethenjelwa kanye nomthamo wokulayisha kakhulu.

Isikhwama se-Silicone

Impahla engenisiwe, ukujiya okungu-3 mm, ingamela izinga lokushisa eliphezulu ibe ngu-180°C. Isikhathi sokuqinisekisa ikhwalithi sigcina iminyaka emi-4 isesimweni esijwayelekile. Ubukhulu bengilazi obungama bungama-36mm. Esikhwameni ngasinye se-silicone, kunama-pcs angu-2 we-teflon meshes ukuvikela isikhwama se-silicone ukuthi singaphulwa.

Ukupholisa ingxenye

Lapho ukushisa kwengilazi sekuphelile, vele ukhiphe i-pallet, uyibeke phezulu emshinini, kukhona abalandeli bokupholisa.

Kunedivayisi yokungeniswa kuthreyi. Lapho ifeni izwa ukuma kwethreyi, izoqala ukusebenza. Kuze kuphele isikhathi esimisiwe.

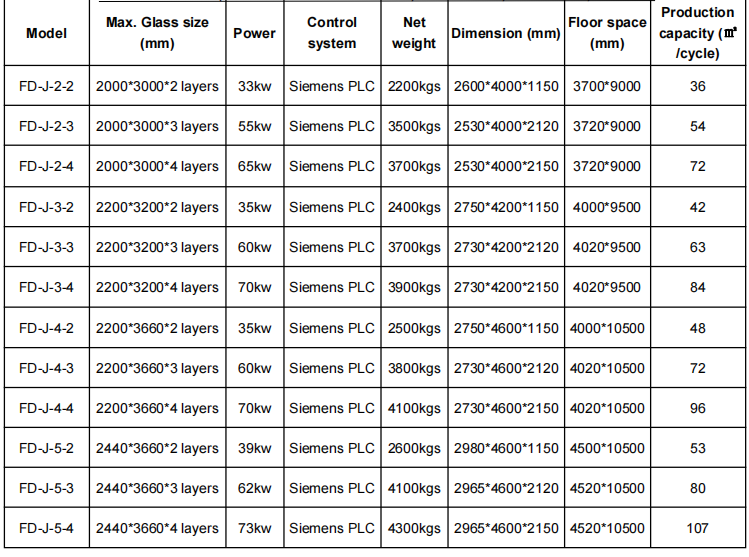

Eminye imininingwane

Xhumana nathi

Taoluo Industrial park, Rizhao City, Shandong, China

Amahora Wokuvula

UMsombuluko ------------ ngoMgqibelo

8:00 am - 18:00 pm

Kunezinhlobonhlobo eziningi

Kunokuhlukahluka okuningi kwamavesi e-Lorem Ipsum atholakalayo, kodwa iningi liye labhekana noshintsho ngandlela thile,

ngamancoko ajovwe, noma amagama angahleliwe angabukeki engakholakali nakancane